Organic Fertilizer Microbe Process

Keywords:

Affiliated Classification:

Municipal Environmental Protection

Counseling:

Organic Fertilizer Microbe Process

Product Details

Technical Brief

The technology can quickly turn organic wastes such as livestock manure, dead leaves, discarded mushroom bags, food/household sludge, fruit and vegetable residues, plant and animal scraps, etc. into organic fertilizers or garden green manure.

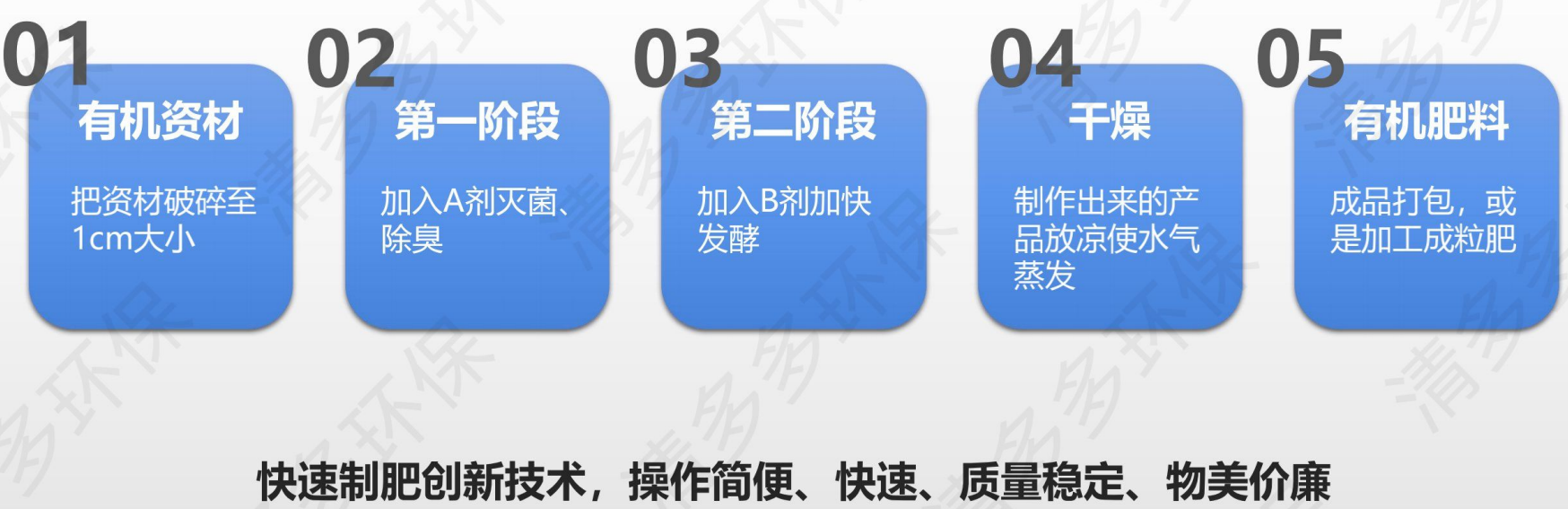

Technical production process:

1. Pre-treatment: For fibrous and hard materials such as dead branches and leaves, fruit and vegetable residues, etc., apply crushing, sieving and other homogenization to increase the efficiency of the subsequent reaction.

2. First stage fermentation: hot air is introduced at the beginning of the process and oxygen-enriched substrate is added to effectively sterilize and reduce odors and quickly achieve the effect of shortening the fermentation time.

3. Second stage fermentation: add catalyst to accelerate fermentation, and moderately introduce hot air to accelerate drying, to shorten all processes to 3 hours.

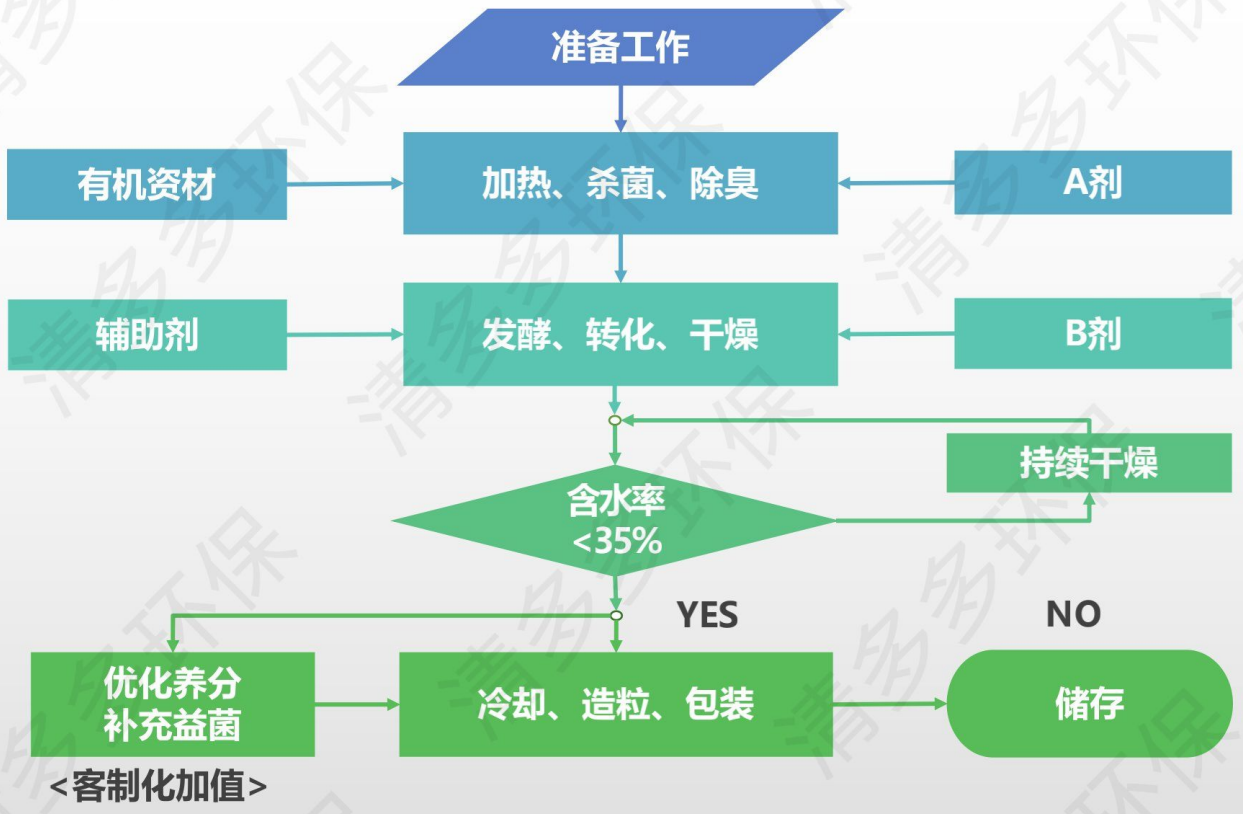

Technological process

Workflow

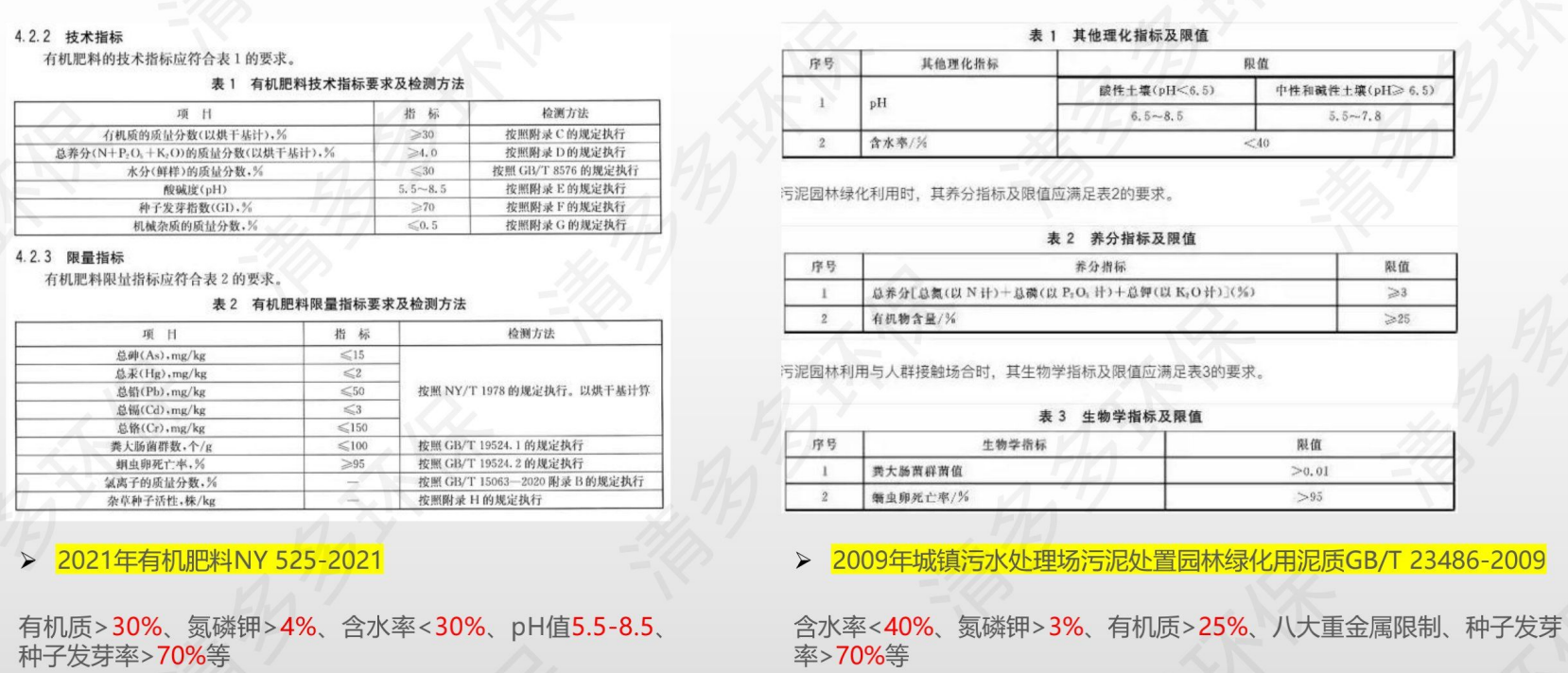

Relevant policy indicators

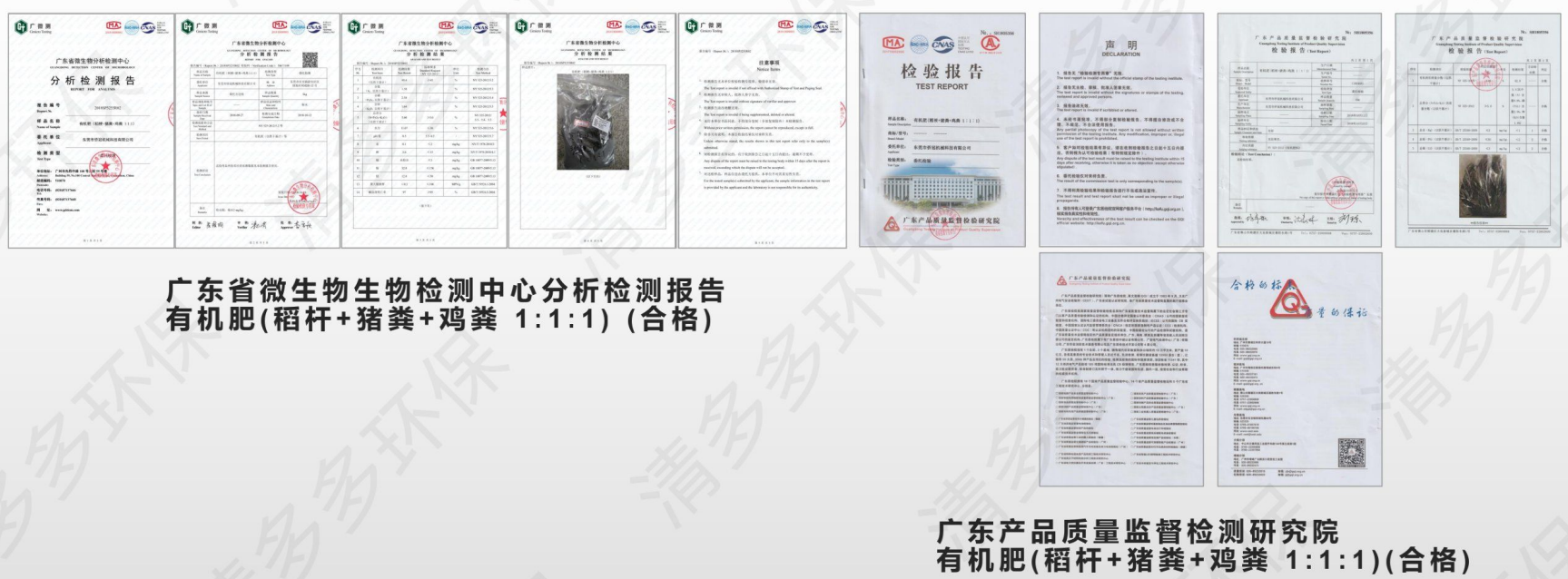

Test Reports

Combined benefits

● Rapid processing: organic waste fertilizer making process in 3 hours.

● Process Advantage: No wastewater, odorless, non-toxic treatment technology.

● Equipment space: High-efficiency equipment that occupies a small space.

● Treatment cost: high catalyst efficiency - high C/P value.

● Operation process: automated process.

● Recycling: The product of the treatment can be used as agricultural fertilizer.

● Optimization of materials: Adding appropriate nutrients and supplementing beneficial bacteria, it can become biological bacterial fertilizer - increasing the added value of the product.

● Agricultural benefits: Reduce the use of chemical fertilizers, produce soil conditioners, activate soil microorganisms, increase the effectiveness of soil nutrients and biological checks and balances.

Practical example

Harbin, Heilongjiang:Four automatic organic fertilizer production lines have been set up, processing 40,000 tons of cow dung as well as 20,000 tons of straw annually.

Fuyuan City, Heilongjiang: Fuyuan 10,000 mu rice base.

Tongjiang County in Sichuan:Cultivation of fire fruit, passion fruit, the introduction of Taiwan's high-quality fruit planting technology, the use of our own production of organic fertilizers, the formation of an organic cycle of the industrial chain of business models

Comparison of other technologies

| concern | Traditional fermentation | General rapid composting methods | This patented fertilizer production technology |

| timing | Time-consuming (2-4 months) | 8 hours ~ 15 days | Within 2~3 hours |

| space requirement | space-consuming | space-saving | Traditional 1/20 area (cubed) |

| matrix | Wastewater, odor | stink |

None Zero Waste/Zero Emission |

| a pathogen | Undercooked may have pathogens | not have | not have |

| greenhouse gas | Significant CO2 emissions, with organic carbon losses typically >20% or more | Organic carbon losses generally >20% or more | few |

| labor cost | Requires a lot of manpower | Requires a lot of manpower | Can be operated by 2-3 people independently |

| equipment cost | High maintenance costs | High maintenance costs | Only 1/3 of traditional |

| maintenance cost | Large-scale turning equipment and odor suppression (energy consumption for water curtain operation and cost of deodorizer) | Large-scale turning equipment and odor suppression | Highly efficient customized equipment |

| transportation cost | height | Local processing reduces transportation and environmental issues | Local processing reduces transportation and environmental issues |

| loss of fertilizer | Nitrogen fertilizer loss of more than 30 to 40% | Loss of ammonia fertilizer >20% or more | Almost no wear and tear |

| Manufacturing conversion rate | About 50%, not immediately usable, need to go through a post-fermentation maturation phase | Cannot be used immediately, need to go through the post-fermentation maturation and drying stage. | Almost 100% |

| product quality | Unhomogeneous, unstable nutrients, containing pest eggs, pathogens and weed seeds | Unhomogeneous, unstable nutrients, some contain pest eggs and pathogens |

Harmless to insect eggs, disease & weed seeds, Enriched with probiotics and ready for immediate application. |

Business model

preceding page

next page

preceding page

next page

Related Products

online message